About Us

Powder Coating is a dry finishing process created by an electric charge that causes a dry powder to fuse to the surface of the metal.

Our company offer a wide range of powder coating services for all kinds of projects. Our experienced and knowledgeable staff can assess your needs and provide you with the best powder coating solution that meets your specifications and budget. We specialize in custom colors, textures, and finishes for both industrial and residential applications. We are dedicated to providing our customers with the highest quality services at competitive prices. With more than 15 years of experience in the powder coating industry, we are committed to providing the best customer service and satisfaction. Contact us today to learn more about our services and how we can help you with your powder coating needs.

SPECIALIZATION TECHNICAL COATING

Epoxy Powder Coatings

Epoxy-Polyester Powder Coatings

Pure Polyester Powder Coatings

Polyurethane Powder Coatings

Anti-Microbial Powder Coating

Electrical Insulation Coating

DECORATIVE COATING

Two Tone Effect

Sparkle Effect

Wood finish

Services

Powder Coating is a dry finishing process created by an electric charge that causes a dry powder to fuse to the surface of the metal.

PRE-TREATMENT PROCESS FOR FERROUS

1. DEGREASING This stage removes oil, grease, dirt and other dust particles to give a clean, surface for next stage in the process (for ferrous &Non Ferrous) Chemical base: Alkaline

2. WATER RINSE To remove the chemical from the earlier stage and make the surface totally free from any contamination prior to entering into next stage in the process.

3. DERUSTING This stage removes rust, Black Carbon, etc.. from the metal and at the same time make the surface little reactive for the next stage in the process.Chemical base: Phosphoric

4. WATER RINSE To remove the chemical from the earlier stage and make the surface totally free from any contamination prior to entering into next stage in the process.

5. PHOSPHATING It gives a deposition of insoluble metal phosphate by chemical reaction. Since the deposited coating forms by a chemical reaction it gives good adhesion and good corrosion resistance to the powder coating film.

Chemical base: Zinc

6. WATER RINSE To remove the chemical from the earlier stage and make the surface totally free from any contamination prior to entering into next stage in the process.

7. PASSIVATION This stage helps in sealing the cavities in the phosphate coating and thus increases the corrosion resistance of the coating.

PRE-TREATMENT PROCESS FOR NON FERROUS (AL, ZINC ALLOYS)

1. DEGREASING This stage removes oil, grease, dirt and other dust particles to give a clean, surface for next stage in the process (for ferrous & Non Ferrous) Chemical base: Alkaline

2. WATER RINSE To remove the chemical from the earlier stage and make the surface totally free from any contamination prior to entering into next stage in the process.

3. HANGING After Phosphating check the component and hanging with Special Hooks, which is matching to the component.

COATING AND BAKING

Our well-trained, skilled and experienced team coats the component with the Electrostatic spray gun, to produce the desired thickness of powder coating on the component. The components are then baked in oven at the required temperature. While Coating and Baking the products are properly placed with the help of special Hooks & Fixtures, to avoid any unwanted touching.

QUALITY SECTION

Inspection of each component happens as per the standard specification. Visual Check Inspection Pinholes Less Coating Orange Pill Shade Variation Coating Thickness Scratch Test Bent Test Impact Test UV Test

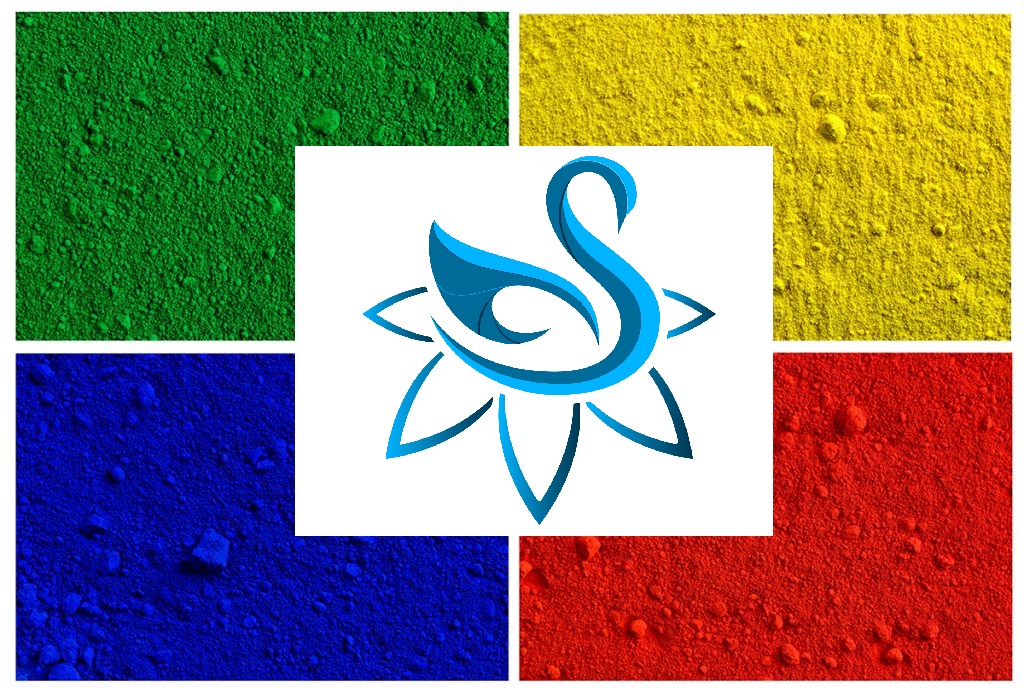

COLORS & FINISHES

COLORS - RAL , IS, Panton, Customized

FINISHES - Glossy, Satin, Matt, Textures, Structures, Clears, Leatherier, Hammer tone, Wrinkle, Metallic & Antique Shades

Why choose us?

Durability, Quality products, Cost effectiveness, Superior finishing, Broad range of products, Delivery of products by deadlines

Durability

Quality Products

Superior Finishing

Clients

Projects

Hours Of Support

Hard Workers

Our Portfolio

- All

- FERROUS

- NON-FERROUS

- COATINGS

Contact Us

854/2/A GIDC, VADODARA

rajhanscoat@gmail.com

+91 9909258348